Industriestandard

der überzeugt

Vom Konzeptauto über komplette Interieurveredelungen bis hin zur Serienfertigung sind wir für sie da

wir sind der Partner, den sie brauchen

Bei jedem neuen Projekt haben wir immer das gleiche Ziel vor Augen: Unsere und vor allem Ihre Anforderungen und Ansprüche zu übertreffen und ein einzigartiges Fahrzeug zu schaffen, das seinesgleichen sucht. Unvergleichliche Freude an Ihrem neuen Fahrzeug ist das beste Ergebnis, das wir Ihnen bieten können. Dabei kümmern sich unsere Experten um Styling-Pakete, vom Design über die Erstellung von Strukturmodellen und Prototyping bis hin zur Produktion fertiger Elemente, entweder einzeln oder in Serie. Nach Ihren Wünschen und Vorstellungen entwickeln wir neue Designs für einzelne Komponenten oder den gesamten Fahrzeuginnenraum.

Alle Polsterungen werden an unserem Hauptstandort in Niederbayern gefertigt. Wir kreieren sie aus hochwertigem Leder oder alternativen veganen Materialien in verschiedenen Farbkombinationen. Wir garantieren ein individuelles Design und die perfekte Verarbeitungsqualität – unabhängig von der Größe der Produktionsserie.

Leistungen

Wir beraten Sie gerne ganzheitlich zu Ihren geplanten Projekten, ganz gleich ob es sich dabei um eine individuelle Anfertigung oder ganze Serienanfertigungen handelt. Angefangen von intensiven Beratungsgesprächen und der Konzeptentwicklung über die Musterwahl der Designs bis hin zur Prototyp-Fertigung und der letztlichen Umsetzung in Klein- oder Großserien.

Sowohl für individuelle Fahrzeugprototypen als auch für exklusive Kleinserien entwickeln wir:

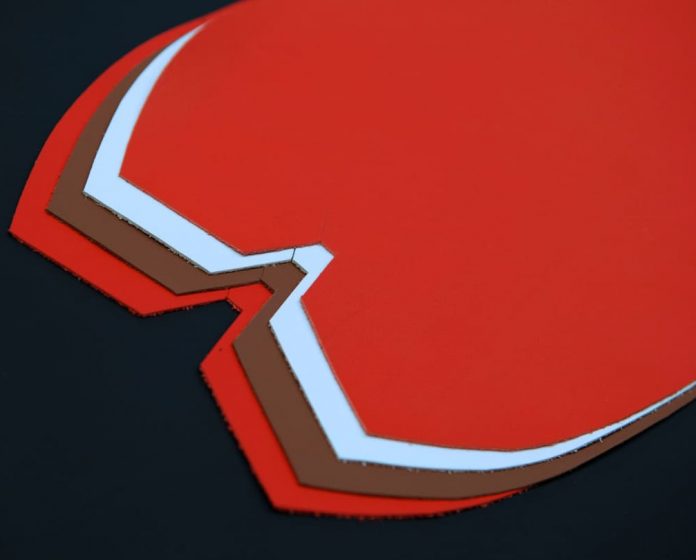

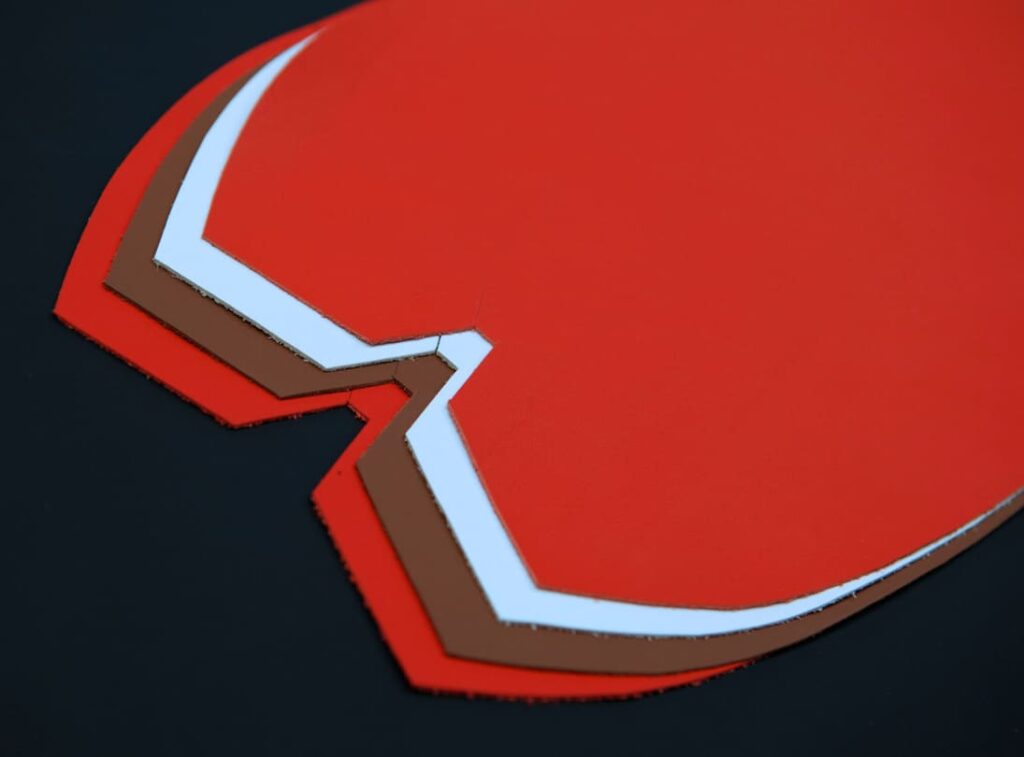

- Kaschierkonzepte

- Nähkleider

- Nähtechnik mit Airbag

- Sitzbezüge

- Materialkombinationen

Fertigung

Ausschließlich an unserem Standort in Weng verarbeiten wir hochwertige Materialien wie Leder und fertigen für den Premiumsektor:

- Individual- und Kleinserienfertigung

- Fahrzeug Auf- & Umbauten

- Anfertigung von Nähkleidern und Sitzbezügen

- Cutterzuschnitte für Prototypen und Serie

- Kaschieren von Prototypen, Musterteilen und Kleinserien

- Baumuster und Einzelstücke

- Prototypen nach CAD-Daten

Inspirationen & Innovationen

Egal ob Steppungen, Stickungen, gelochte Felder oder alles in einem, wir realisieren Ihre Designwünsche auf allen Bauteilen.

Auch Individualnähte, Positiv- oder Negativprägungen sind für uns kein Problem. Wir arbeiten stehts nach dem Motto “alles ist möglich”.

Maschinenpark

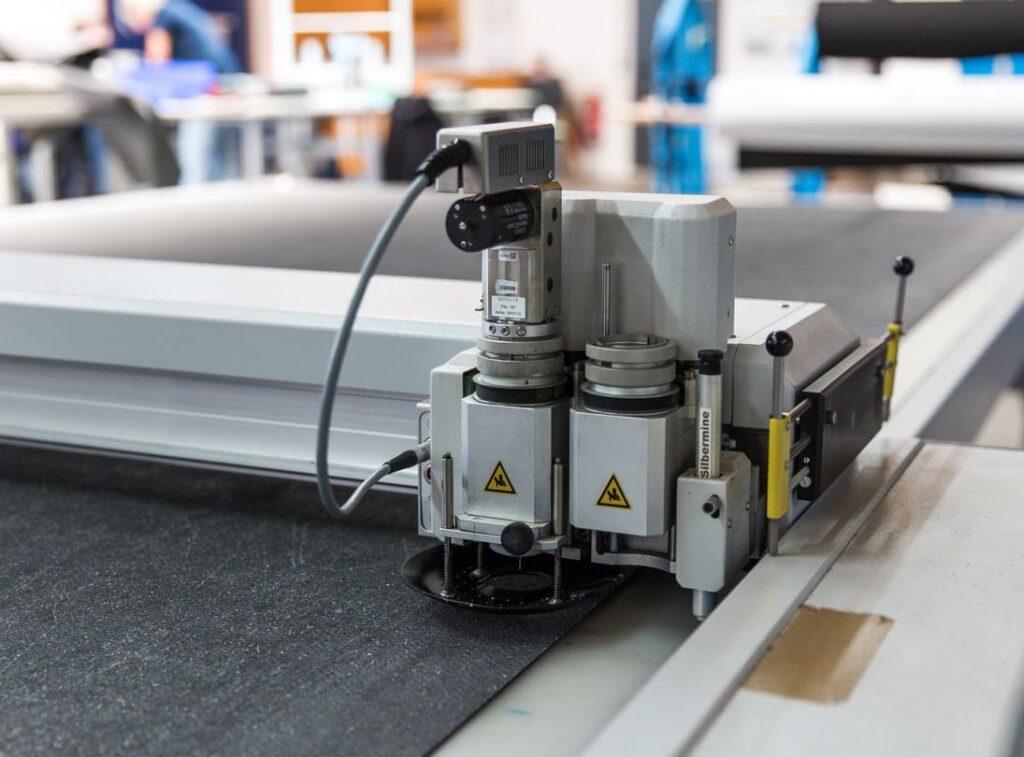

Unsere einzigartig veredelten Fahrzeuge entstehen in einem modernen Maschinenpark, den wir ständig erweitern, damit unsere Produkte höchsten Standards entsprechen. Unsere Produktionsanlagen sind schnell umrüstbar und ermöglichen damit die Herstellung von kleinen Serien für limitierte Polster. Dafür nutzen wir u. a. das folgende hochmoderne Equipment:

- Lederhäute-Scan-Anlage zur Erkennung von Naturmerkmalen

- Präzisionseinlagencutter für diverse Materialien

- Spaltmaschine, Schärfmaschine, Prägepresse

- Diverse Nähmaschinen inklusive Airbagnähmaschine mit Dokumentationssoftware

- Kleberspritzanlage

- Membrankaschieranlage für Technikumszwecke

- Diverse Einhandpressen und Sattlereiarbeitsplätze

- Nähautomat mit Ein-Kopf Stick- und Punch-Funktion

Unterstützung Serienanlauf

Für die reibungslose Umsetzung der Kaschierkonzepte und Designarbeiten sorgt nicht zuletzt unsere aktive Begleitung bei Verlagerung und Aufbau von technischen Anlagen sowie unsere fachliche Unterstützung in der Werkzeug-Konzeptphase.

Grundsätzlich reicht unsere Unterstützung bis hin zur Serienanlaufphase und schließt auch die Anfertigung von Prototypen und Kleinserien mit ein.

Technische Dienstleistungen

- Entwicklungsdienstleistung

- Industrialisierung

- Zuschnittsentwicklung

- Zuschnittsoptimierung

- Kompetenzteam Oberfläche Interieur

- Prüfen, Sortieren & Nacharbeit zur Sicherstellung der Qualitäts-Anforderungen

- Lieferantenmanagement

Weltweit im Einsatz

In den vergangen 15 Jahren war Zettl i-tec (ehemals Zettl Interieur) in den unterschiedlichsten Regionen der Erde im Einsatz. Zu den Stationen gehören unter anderem die Länder Österreich, Tschechien, Polen, Slowenien, Rumänien, Italien, Spanien, England, die Vereinigten Staaten von Amerika, Mexiko und Südafrika. Die Firmengruppe Zettl ist global vernetzt und kann so schnellstmöglich auf neue Anforderungen von Kunden eingehen und die Fertigung betreuen.

- 32 Projekte realisiert

- 8.054 Materialkombinationen

- 15 zufriedene Kunden

- 32 Projekte realisiert

- 8.054 Materialkombinationen

- 15 zufriedene Kunden

- 461 Projekte realisiert

- 32.164 Materialkombinationen

- 165 zufriedene Kunden

- 12 Projekte realisiert

- 468 Materialkombinationen

- 3 zufriedene Kunden

- 17 Projekte realisiert

- 4.189 Materialkombinationen

- 2 zufriedene Kunden

- 17 Projekte realisiert

- 1.682 Materialkombinationen

- 5 zufriedene Kunden

Partnerschaft auf Augenhöhe

Wir verstehen uns als Ihr Partner auf Augenhöhe und unterstützen Sie mit unserem umfassenden Know-how und unserer langjährigen Erfahrung. Lassen Sie uns gemeinsam die Zukunft des Interieurs in der Automobilindustrie gestalten.