Industry standard

that convinces

From concept cars and complete interior refinements to series production, we are there for you

We are the partner you need

With every new project, we always have the same goal in mind: to exceed our and, above all, your requirements and demands and to create a unique vehicle that is second to none. Incomparable enjoyment of your new vehicle is the best result we can offer you. Our experts take care of styling packages, from design to the creation of structural models and prototyping to the production of finished elements, either individually or in series. We develop new designs for individual components or the entire vehicle interior according to your wishes and ideas.

All upholstery is manufactured at our headquarters in Lower Bavaria. We create them from high-quality leather or alternative vegan materials in various color combinations. We guarantee an individual design and perfect workmanship - regardless of the size of the production series.

Services

We are happy to provide you with comprehensive advice on your planned projects, regardless of whether they involve individual production or entire series production. Starting with in-depth consultations and concept development through to the selection of design samples, prototype production and the final implementation in small or large series.

We develop both individual vehicle prototypes and exclusive small series:

- Laminating concepts

- Sewing clothes

- Sewing technology with airbag

- Seat covers

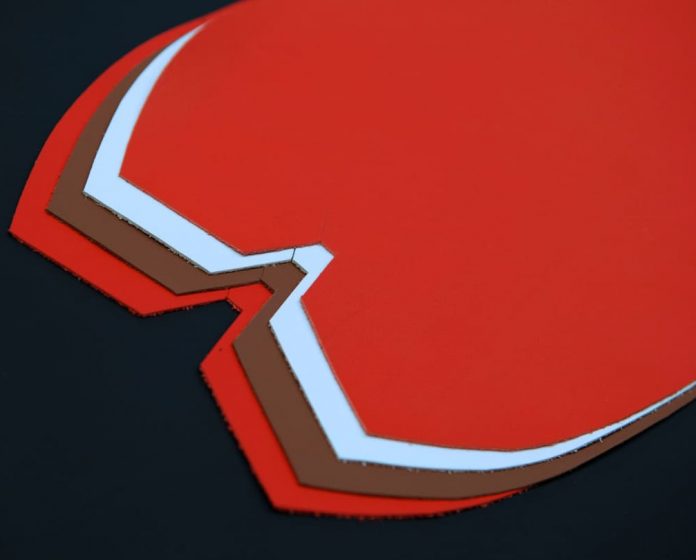

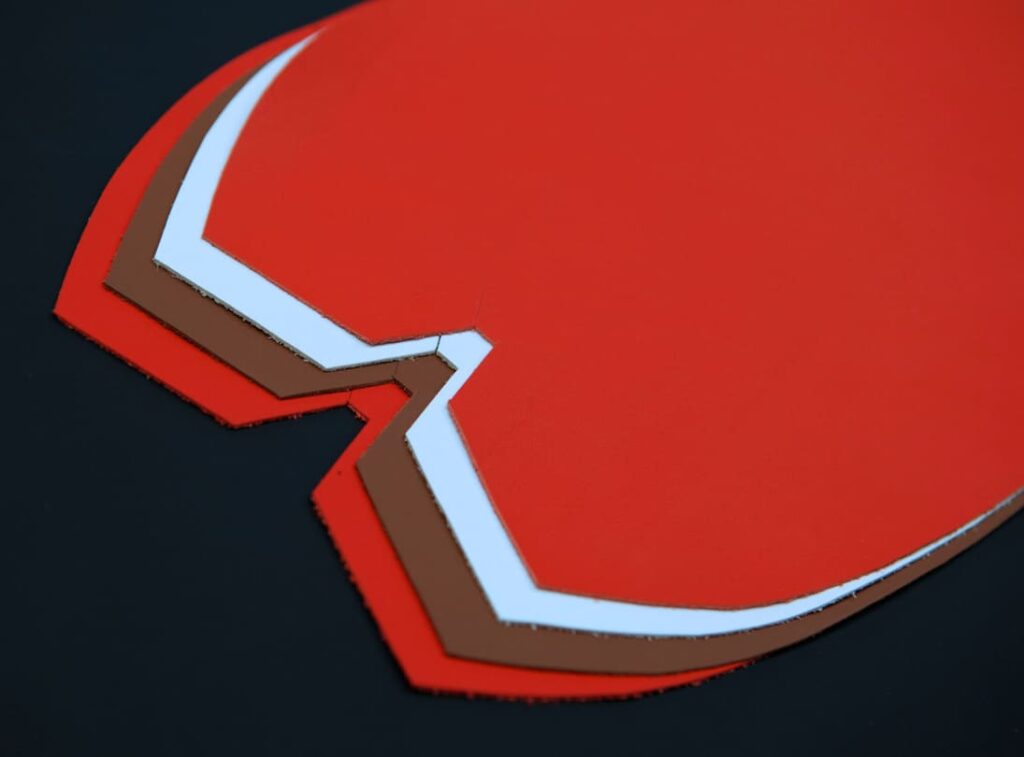

- Material combinations

Manufacturing

We process high-quality materials such as leather and manufacture for the premium sector exclusively at our site in Weng:

- Individual and small series production

- Vehicle superstructures & conversions

- Production of sewing garments and seat covers

- Cutter cuts for prototypes and series production

- Lamination of prototypes, sample parts and small series

- Prototypes and individual pieces

- Prototypes according to CAD data

Inspirations & innovations

Whether quilting, embroidery, perforated fields or all in one, we realize your design wishes on all components.

Customized seams, positive or negative embossing are also no problem for us. We always work according to the motto "anything is possible".

Machinery

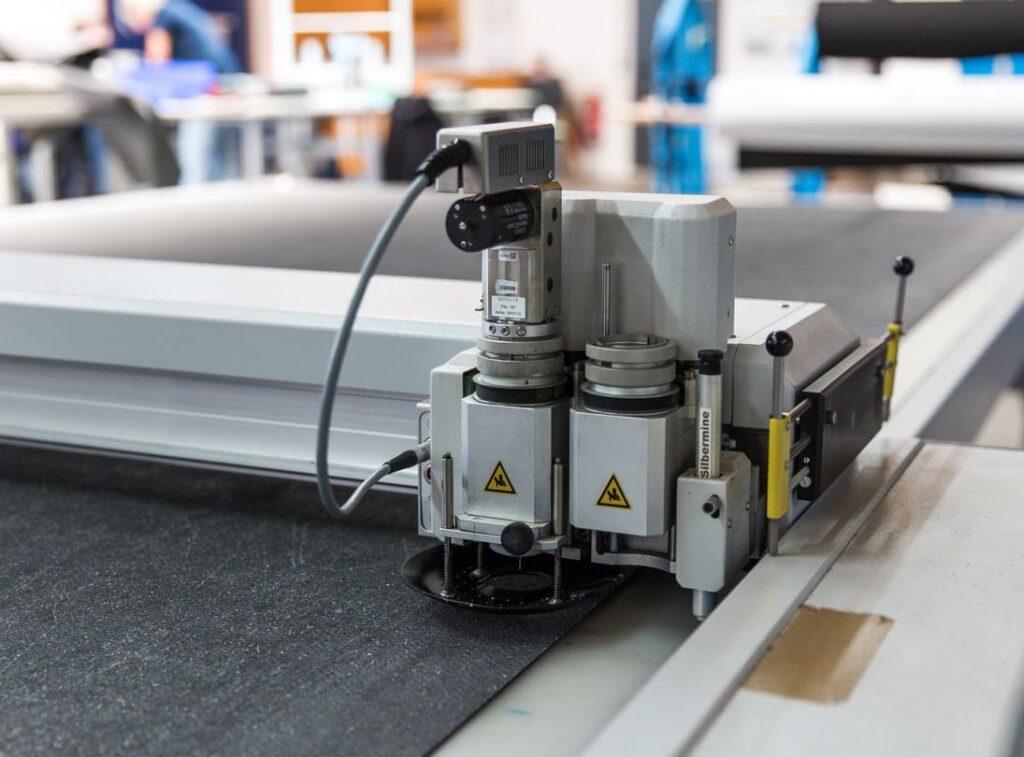

Our uniquely finished vehicles are created in a modern machine park, which we are constantly expanding to ensure that our products meet the highest standards. Our production facilities can be converted quickly, enabling us to manufacture small series for limited edition upholstery. We use the following state-of-the-art equipment for this purpose:

- Leather hides scanning system for the recognition of natural features

- Precision insert cutter for various materials

- Splitting machine, sharpening machine, embossing press

- Various sewing machines including airbag sewing machine with documentation software

- Adhesive spraying system

- Membrane laminating system for pilot plant purposes

- Various one-hand presses and saddlery workstations

- Automatic sewing machine with single-head embroidery and punch function

Support series start-up

Last but not least, our active support during the relocation and installation of technical systems and our technical support in the tool concept phase ensure the smooth implementation of the laminating concepts and design work.

In principle, our support extends to the series start-up phase and also includes the production of prototypes and small series.

Technical services

- Development service

- Industrialization

- Cutting development

- Cutting optimization

- Interior surface competence team

- Checking, sorting & reworking to ensure quality requirements are met

- Supplier management

In use worldwide

Over the past 15 years, Zettl i-tec (formerly Zettl Interieur) has worked in many different regions of the world. Stations include Austria, the Czech Republic, Poland, Slovenia, Romania, Italy, Spain, England, the United States of America, Mexico and South Africa. The Zettl Group is globally networked and can therefore respond as quickly as possible to new customer requirements and support production.

- 32 projects realized

- 8,054 Material combinations

- 15 satisfied customers

- 32 projects realized

- 8,054 Material combinations

- 15 satisfied customers

- 461 projects realized

- 32,164 Material combinations

- 165 satisfied customers

- 12 projects realized

- 468 Material combinations

- 3 satisfied customers

- 17 projects realized

- 4,189 Material combinations

- 2 satisfied customers

- 17 projects realized

- 1,682 Material combinations

- 5 satisfied customers

Partnership at eye level

We see ourselves as your partner at eye level and support you with our comprehensive expertise and many years of experience. Let's shape the future of interiors in the automotive industry together.